Electroplating

key notes :

What is Electroplating?

- Electroplating is a process in which a metal coating is applied to an object’s surface by using electrical current. It is commonly used to improve the appearance and durability of various items.

How does Electroplating Work?

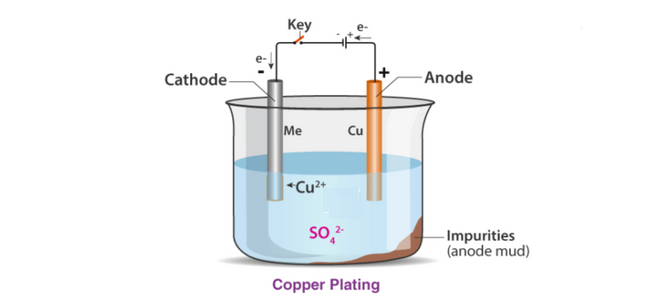

- Electroplating involves two key components: an anode (positive electrode) and a cathode (negative electrode), both immersed in an electrolyte solution.

- The object to be plated is connected to the cathode, while a metal (often the same as the coating metal) is connected to the anode.

- When electric current is applied, metal ions from the anode dissolve in the electrolyte and are deposited onto the cathode (the object) as a thin, even layer.

- Purpose of Electroplating:

- Improve Appearance: Electroplating can enhance the appearance of objects by giving them a shiny, metallic finish.

- Prevent Corrosion: It provides a protective layer that prevents the underlying material from corroding.

- Increase Durability: Electroplating can make objects more resistant to wear and tear.

- Create Decorative Finishes: It’s used for decorative purposes, such as creating gold or silver finishes on jewelry.

- Common Metals Used in Electroplating:

- Chromium: Used for chrome plating on automotive parts and kitchen appliances.

- Nickel: Often used as an undercoat before applying another metal, like chrome or gold.

- Gold and Silver: Used for jewelry and decorative items.

- Copper: Used for electrical connectors and as a base layer for other metals.

- Applications of Electroplating:

- Jewelry making: Gold and silver electroplating for jewelry pieces.

- Automotive industry: Chrome plating for car bumpers and trim.

- Electronics: Copper plating on printed circuit boards.

- Household items: Nickel plating on faucets and kitchenware.

- Aerospace: Electroplating is used to protect aircraft components from corrosion.

- Environmental Concerns:

- Electroplating can produce waste and potentially harmful chemicals, so proper disposal and waste management are crucial.

- Regulations and practices have been developed to minimize the environmental impact of electroplating processes.

- Safety Precautions:

- Electroplating involves the use of electricity and chemicals, so safety measures like wearing protective gear and working in well-ventilated areas are essential.

Let’s practice!