Electroplating

electroplating by Delta publications

Key Notes :

Definition of Electroplating:

- Electroplating is a process of coating a thin layer of metal onto another metal using an electric current. This is done to improve the appearance, durability, or resistance of the metal object.

How Electroplating Works:

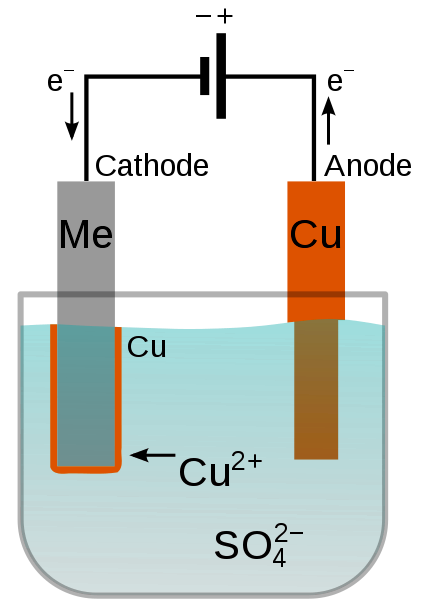

- In electroplating, the object to be plated (cathode) is connected to the negative terminal of a power supply.

- The metal that will coat the object (anode) is connected to the positive terminal.

- Both the object and the metal are placed in a solution containing a salt of the metal to be plated.

- When electricity passes through the solution, metal ions are transferred from the anode to the cathode, forming a thin metal layer.

Common Uses of Electroplating:

- Decorative purposes: Jewelry, cutlery, and coins are electroplated to give them a shiny, appealing finish (e.g., silver or gold plating).

- Corrosion resistance: Metals like iron are electroplated with zinc (galvanization) to prevent rusting.

- Wear resistance: Tools and machinery parts are plated with harder metals (like chromium) to reduce wear and tear.

- Improving electrical conductivity: Copper or silver plating is done to improve the conductivity of electrical components.

Examples of Electroplating:

- Gold-plated jewelry.

- Chrome plating on car bumpers.

- Zinc coating on steel for corrosion resistance (galvanization).

Advantages of Electroplating:

- Enhances the appearance of objects by giving them a polished, shiny finish.

- Protects metals from corrosion and rust.

- Increases the hardness and durability of materials.

- Improves electrical conductivity in electronic components.

Disadvantages of Electroplating:

- It requires careful handling of chemicals, which can be hazardous.

- The process can be expensive depending on the materials used.

- Disposal of waste chemicals may cause environmental harm if not managed properly.

Electroplating vs. Galvanization:

- Electroplating is a more controlled process, while galvanization usually refers to coating steel with zinc to prevent rust.

Let’s practice!